Process Flow

Selling Points

Size: Approximately 200m²

- Thanks to the spacious area, we can consider setting up curtains or clean booths within the cleanroom to create an area with even higher cleanliness levels.

- If a cleanroom is not required, there are other inspection rooms available.

Performance of Class 1000

- Measured with a particle counter when inspecting automotive semiconductor parts, this reflects actual achievement.

- The room maintains a constant positive pressure environment to prevent contamination from being released to the outside.

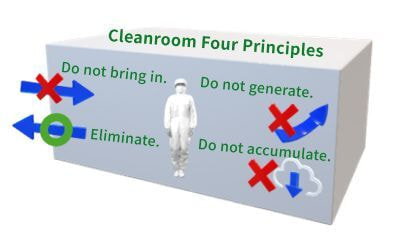

Unique Methods to Maintain Cleanliness

- We have established four principles for the cleanroom and are committed to them daily.

- We wear cleanroom suits.

- We have established rules for which items can and cannot be brought into the cleanroom.

- We are also creative about our indoor cleaning methods.

Years of Inspection Experience

- Since the company’s foundation 50 years ago, we have continuously conducted inspections.

- We have acquired significant know-how from these years of sustainability.

Genre-less Inspection Experience

- We recently started ceramics, thus urgently needed to develop skilled individuals for ceramic inspection.

- This variety of inspection experience across various industries leads to smooth launches of new projects.

Maintaining Inspection Accuracy

- We have developed a unique inspector certification system and training curriculum.

- We have also established a unique maintenance check system.

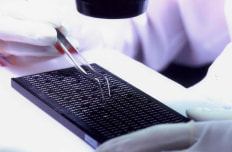

Handling of Micro Products

- We select suitable tools (such as tweezers) for each product.

- Through a custom practice curriculum, handler specialists are created.

-

Skilled handling of tweezers

☆Firstly, please consult with us. CONTACT

Innovative Ideas for Rapid Development, Consistent Inspection, and Efficiency

-

Example 1: Use of Tablets

- We deal with a large number of physical photos, such as defective samples and feedback information with inspections. Therefore, we initiated management via tablet, which contributes to inspection accuracy and cost reduction.

-

Tablets

-

Example 2: Initial Layout for New Projects

- or new inspection projects, understanding inspection standards and common understanding of defects are crucial. For early stage, consistent inspection-capable personnel, we design a layout that allows for easy idea exchange. Later, when inspectors become independent, conversation is minimized and prevention of mixing different items becomes critical, hence we modify the layout.

-

first layout

Translation Explanation

Industry |

Products |

Inspection Contents |

Automotive parts |

|

|

Semiconductor/ |

|

|

Other parts |

|

|

Inspection Method |

|

|||

Pre-inspection Status |

|

|||

Post-inspection Delivery Status |

|

|||

Quantity and Price

-

-

We will consider your requests starting from a single piece.

-

We can provide estimates according to your needs, such as price per spot quantity and price per monthly production quantity in mass production.

-

Introduction of processes and equipment

591-4, Ishigaya, Yoshiwa, Ube City, Yamaguchi Prefecture 759-0134

0836-62-1531

Dial your international access code, then 81 for Japan, then 836-62-1531 while omitting the leading ‘0’.