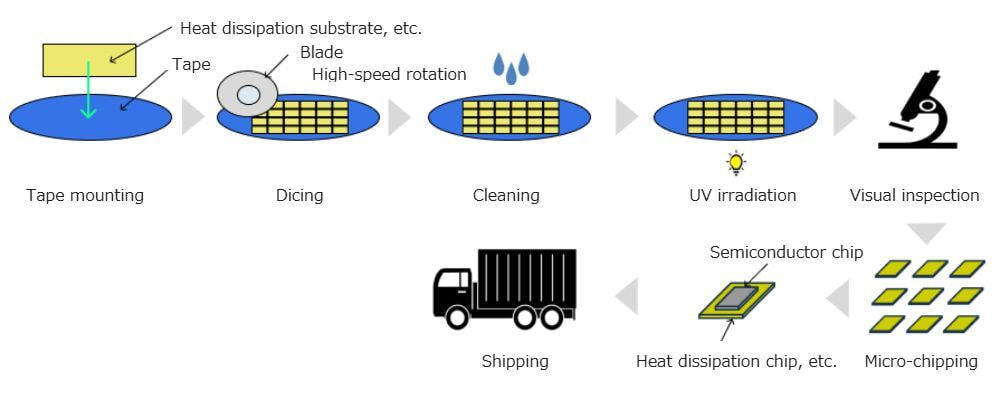

Process Flow

Selling Points

- High Precision

- Capable of processing in line with substrate shrinkage

- Ultra-pure water cleaning

- Extensive experience

- Use of program and conditions

- Yield 30% → 100% achieved

- Productivity doubled

- Numerous cases of successful manufacturing where other companies struggled

- Experience in reducing tape residue

☆Firstly, please consult with us. CONTACT

Possible Specifications and Experience

Materials |

Processing Experience Available |

・AlN (Aluminum Nitride) Skilled |

||

Processing Experience Available |

・Al2O3 (Sapphire) |

|||

No Experience |

・Si3N4 (Silicon Nitride) |

|||

Front and Back Film Material of the Material |

Ti, Ni, Pd, Ag, Sn, Pt, Au, Pb, Glaze, etc. ※The adhesion compatibility between the material and the tape, as well as the We at LEAD Co., Ltd. will verify the optimal processing conditions and program. |

|||

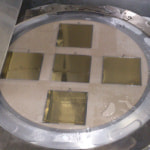

Original Size of the Material |

・For round shapes, up to Φ8 inches (Φ200mm) ・For square shapes, up to □141x141mm ・Thickness: It depends on the hardness of the material, but approximately 0.1 to 5mm |

|||

Chip Size After Dicing |

・Chip Size: From □0.3mm upwards ・Accuracy: Depends on the difficulty of processing the material. |

|||

Supply and Shipment Format

| Application Examples | ||||

Supply Form of Material |

|

|||

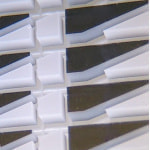

Shipping Form |

|

|||

Other Supply Examples |

|

|||

Quantity and Price

-

We will consider your requests starting from a single piece.

-

We can provide estimates according to your needs, such as price per spot quantity and price per monthly production quantity in mass production.

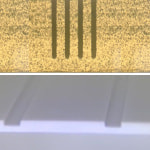

Major Processing Achievements

Process and Equipment Introduction

591-4, Ishigaya, Yoshiwa, Ube City, Yamaguchi Prefecture 759-0134

0836-62-1531

Dial your international access code, then 81 for Japan, then 836-62-1531 while omitting the leading ‘0’.